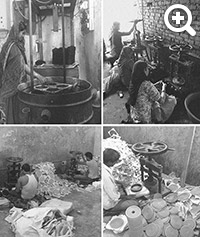

Jupiter Paper Cones, a name known then and a name known now as well was led by Mr. S.A. Hameed and his wife Mrs. Zubeda as a handmade paper making unit. Their quest of being better than the best led them establishing a new unit to make speaker paper cones manually.

The couple foresighted the demand and moved ahead with commitment for the approaching business laid on the foundation of principles and innovation.

When these speaker paper cones were marketed to the speaker manufacturers, the company was well applauded for quality and durability. Upon witnessing such positive feedbacks and rising demand, Mr. Hameed along with his eldest son, Mr. Rashid executed the plan of utterly diversifying their business in the manufacturing of Speaker’s soft components.

In order to do so, they raised the production capacity of paper cones and initiated the process of making other speaker component related products, dampers, dustcaps etc.

Mr. Rashid and his younger brothers Mr. Sayeed and Mr. Khalid decided to upgrade the production expertise and to use better machinery in order to deliver better. As a result, they collaborated with one of the leading Japanese Company and started using the then latest technology.

Their action was well-paid off because few years down the line, the company’s clientele included Philips, LG, Samsung, BPL, Sony, Videocon, Onida etc.

Stepping its path towards audio perfection, the company got its SWOT analysis done and worked upon it. The management converted optimized its opportunities to set-off the weaknesses and strengthened itself enough to set aside all threats, thus moving one step ahead of what it was.

In the year 2001, the company established its own automatic production unit to manufacture speaker’s soft parts, proving that Jupiter Paper Cones is all about getting better and better with each passing day.

Driven by an unmatched legacy of innovation along with the dedication to quality, Jupiter Paper Cones exemplifies the management’s hard work and innovative approach towards business. We believe there is always a scope for betterment and considering the present ourselves as our biggest future competitor, we keep upgrading.

In the year 2012, we updated our fully automatic and efficiently technical production unit with the utmost modern technology so that we fulfil the requirements of our leading customers beyond par.